ADA signs are meant to ensure accessibility for individuals with disabilities. Throughout the States, ADA-compliant signage is a legal requirement that businesses must fulfill. However, even if you have ADA signage, not all ADA signs meet the necessary standards set forth by the law. Many signs fail due to poor design, incorrect placement, or low-quality materials, which may lead to compliance issues, fines, and frustrated visitors.

At Tupp Signs, we provide businesses with high-quality ADA signage from Graphic Components—a trusted manufacturer known for precision, durability, and compliance. Here’s why most ADA signs fail and how Graphic Components delivers signage that meets and exceeds industry standards.

Key Takeaways

- Many ADA signs fail due to incorrect Braille, poor contrast, improper placement, and low-quality materials.

- Properly designed ADA signage must feature accurate Braille and tactile lettering, high contrast, and be positioned at the correct height.

- Low-quality signs can fade, crack, or lose readability, making them non-compliant with ADA standards.

- Graphic Components ensures precision manufacturing, durable materials, and non-glare finishes for reliable, accessible signage.

Why Do Most ADA Signs Fail?

Despite ADA requirements being clearly outlined, many businesses unknowingly install mass produced ADA signage that fails to comply in some way. Take a look at the ADA signage you have installed. If any of the following issues are noted, consider getting new ADA signage immediately:

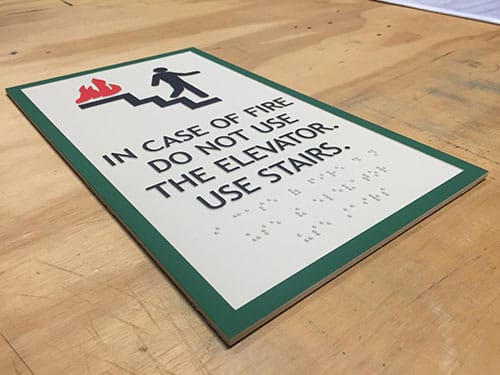

Incorrect Braille and Tactile Lettering

ADA signage must include Grade 2 Braille and raised tactile lettering that are both accurate and readable. The Braille dots must be the correct size, typically 0.039 inches in diameter, with precise spacing between them, and positioned below or next to the corresponding tactile text. Many signs fail to meet these standards because the Braille dots are too small, the spacing is too tight, or the positioning is incorrect. Additionally, the tactile lettering should be raised at least 1/32 of an inch from the surface. If the Braille is unreadable or incorrectly positioned, the sign is considered non-compliant and cannot serve its intended purpose for individuals who are visually impaired.

Poor Contrast and Visibility

Signs must have high contrast between the background and text. The standard requires a contrast ratio of at least 70%, meaning that dark text should be placed on a light background, or vice versa. Many businesses, however, opt for colors that are too similar in tone, resulting in text that blends into the background and is difficult to read. For example, using dark gray text on a black background is not only aesthetically poor but can also make it impossible for visually impaired people to read the sign. Compliance with contrast guidelines is critical to improving accessibility and ensuring readability for all individuals.

Improper Placement

ADA-compliant signs must be installed at specific heights and locations to be accessible. According to the regulations, signs should be mounted between 48 and 60 inches from the ground to the center of the sign for proper viewing. They must also be placed where they are not obstructed by doors, windows, or other structures, and should be in areas that are easy to find and read.

If signs are positioned too high, too low, or in areas where they are hard to reach or read (such as around corners or behind doors), they fail to meet ADA standards. Improper placement can prevent individuals from locating essential facilities, such as restrooms or emergency exits, which compromises the overall accessibility of the space.

Low Quality Materials

In order to maintain compliance, you need ADA signs that are durable and long-lasting. You do not want signage that is made with cheap materials, as these will deteriorate quickly, particularly when exposed to direct sunlight or humidity. Signs made from low-quality materials may fade, causing the text to become unreadable, or the raised Braille and tactile lettering may lose their prominence. Additionally, surfaces can peel, crack, or discolor, all of which diminish the sign’s effectiveness and accessibility.

Lack of ADA-Required Non-Glare Finish

Glossy, reflective, or shiny surfaces can make it difficult for individuals to read signs, especially in bright or direct lighting. ADA guidelines specify that signs must have a non-glare finish to prevent light from reflecting off the surface and obscuring the text. A non-glare finish ensures that the sign remains legible under various lighting conditions, whether in direct sunlight or artificial lighting. Many businesses overlook this requirement, opting for shiny finishes that may look aesthetically pleasing but hinder the sign’s primary purpose of providing clear, accessible information.

How Does Graphic Components Make High-Quality ADA Signage?

Graphic Components is a leader in ADA signage fabrication, meaning that any ADA sign you receive from them will meet all the legal requirements while still maintaining a beautiful appearance. Here are some reasons their signs are a notch above the rest:

1. Precision Manufacturing

Graphic Components ensures proper Braille spacing, raised lettering, and high-contrast color combinations so that every sign meets ADA standards. Advanced technology guarantees accuracy in every detail.

2. Durable Materials

Their signs are made from long-lasting materials like acrylic, metal, and UV-resistant finishes, ensuring they remain readable and professional-looking for years.

3. Customization Options

Businesses can choose from a variety of colors, fonts, and styles to maintain brand consistency while staying compliant. Graphic Components offers customization without sacrificing accessibility.

4. Non-Glare, Easy-to-Read Finishes

All signs feature matte, non-glare surfaces that improve visibility under various lighting conditions, making them accessible to all users.

Contact Tupp Signs to Upgrade Your ADA-Compliant Signage Today

Don’t let poor quality ADA signage drag your business down. You can avoid the trouble by upgrading to high-quality ADA-compliant signs from Graphic Components with Tupp Signs. Our team will ensure your signage needs, as well as all legal requirements, are met—all while complementing your brand identity.

Call us today at 866-324-7446 to discuss your ADA signage needs and get compliant with confidence.